hardness test nomograph|hardness testing methods pdf : service Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well as quality . WEB7 de dez. de 2023 · Confira as dezenas sorteadas, os ganhadores e o valor do prêmio da Mega Sena 2665, realizada em 07 de dezembro de 2023. Veja também as faixas de .

{plog:ftitle_list}

web28 de set. de 2021 · O que eu digo e falo sempre quem precisa andar armado não anda, só anda quem não precisa cadê o desarmamento dessa galera tiraram a defesa de quem é inocente não que seja o caso desse aí, arma não mata ninguém pessoas matam pessoas então sou fortemente a favor de andar armado o cidadão de bem.

The Brinell hardness test involves indenting a material with a hard sphere under a specific load. Two diameters (x and y axis) of the indentation are measured, and the hardness value is . After obtaining the nine total hardness numbers of the steel specimens (three tests for tree different pieces) a nomograph was used to estimate the tensile strength. The “HB” .

The obtained results made it possible to determine the nature of the hardness distribution over the thickness of the sample, to establish the thickness of the decarburized .The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .

Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well as quality .In regular Rockwell testing the minor load is always 10 kgf (kilograms of force). The major load can be any of the following loads: 60 kgf, 100 kgf or 150 kgf. No Rockwell hardness value is .

The test results enabled empirical equations for the relationship between the Brinell hardness of steel and its strength parameters to be derived. The research work was .To calculate Vickers hardness number (VHN) using SI units one needs to convert the force applied from newtons to kilogram-force by dividing by 9.806 65 (standard gravity). This leads .

Based on the power-law stress–strain relation and equivalent energy principle, theoretical equations for converting between Brinell hardness (HB), Rockwell hardness (HR), and Vickers hardness (HV) were established.

Standard Test Method for Portable Hardness Testing by the Ultrasonic Contact Impedance Method, ASTM (2010). ISO 14577-1:2002. Metallic Materials – Instrumented Indentation Test for Hardness and Materials Parameters. – Part 1: Test Method, Switzerland (2002). DSTU EN ISO 6506-2:2019 Materials of metal. Brinell hardness test. Part 2.The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series measurements or mappings are very often carried out using this met-hod. However, it may not be suitable for very soft or highly textured materials, while alternative .A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the .A nomograph is an estimate of the amount of antibody passed to a litter of pups from the mother via her colostrum. During the puppy’s first hours of life, its intestinal tract is able to allow colostral antibody to be absorbed into the bloodstream. . Nomograph testing helps us understand the best timing of vaccination to assure a litter .

A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .

tobacco moisture meter gmk-3306

what is a hardness test

View Lab - Lab 3 from CE 2310 at Purdue University. Lab 3: Hardness Test CE 23100-002, Monday 9:30 Ajay Sharma Date Due: February 22, 2017 1 ABSTRACT The objective of this lab is to use the Brinell . and from there the tensile strength of the material was determined using the Hardness Test Nomograph. The same procedure was followed using .In materials science, hardness (antonym: softness) is a measure of the resistance to localized plastic deformation, such as an indentation (over an area) or a scratch (linear), induced mechanically either by pressing or abrasion.In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals such as .

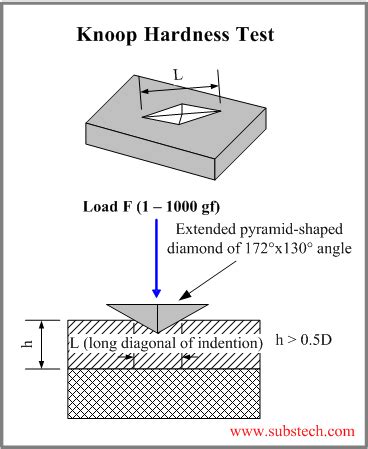

Therefore, different loads are used for hardness testing of different materials. Hard metals such as steels require a 3,000 kgf load while brass and aluminum involve the loads of 2,000 and 1,000 or 500 kgf, . • Learn how to use the Nomograph to obtain the corresponding tensile strength from the hardness numbers.Brinell Hardness Testing: Involves applying a known load to the surface of the test sample via a hardened steel or carbide ball; Vickers Hardness Testing: Utilises an optical measuring system to measure the area of the impression; Knoop Hardness Testing: Employs a diamond penetrator to impress a sample;Mohs Hardness Test: This qualitative test ranks minerals based on their scratch resistance against standard materials with known hardness values. It’s commonly used in geology and mineralogy for mineral identification. These hardness testing methods serve various purposes, from quality control in manufacturing processes to material selection .

These ion measurements can be found on your local water report or can be measured using a home water test kit or by sending a sample of your water to a lab. Note – all of the equations are in parts per million (ppm) – first we can determine the effective hardness: Effective_hardness = Ca_ppm/1.4 + Mg_ppm/1.7. If working from the Alkalinity .

Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended. Characteristics and Application of Vickers Hardness In Rockwell hardness testing, HRA, HRB, and HRC represent three different scales: Scale A, Scale B, and Scale C. The Rockwell test is a common indentation hardness test. All three scales begin with an initial .

Based on the experimental studies and the corresponding analysis of regulatory documents governing the hardness measurements by the Brinell method, the methodology for determining the hardness of high-strength sheet steels was developed. It allows one to obtain more accurate values of some characteristic cases that led in practice to issues of the . Brinell hardness test is an indentation hardness test.It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms) pushes the ball against the surface of the .

Perform the Mohs Hardness Test. The Mohs hardness test is easily performed. You need examples of items with known hardness values. Handy materials include: your fingernails (2.5) a copper coin or piece of chalk (3.5) a pocket knife or piece of glass (4.5-5.5) a quartz point or unglaze porcelain (7.0) a hardened drill bit (8.5)

The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the test indentation is very small in a Vickers microhardness test, it is useful for a variety of applications such as: testing very thin materials like foils or measuring the surface . A scratch hardness test is generally used for minerals, giving a wide range of hardness values in a Mohs scale at minimum and maximum values of 1 and 10 respectively. For example, talcum provides the lowest value of 1 while diamond gives the highest of 10. The basic principle is that the harder material will leave a scratch on a softer material. . Hardness values .

rockwell hardness testing

A DIY water hardness test works by changing color to indicate the minerals present in the water. You can compare the color of the strip to the color chart, which will help you to determine your water hardness. You can buy a hard water test kit online or at your local hardware store for less than . Brinell hardness measurements using a stationary and portable hardness tester, tests of the chemical composition and microstructure, the static tensile test, Brinell hardness measurements across the material’s thickness. The Brinell hardness measurements were carried out in accordance with standard EN ISO 6506–1:2014 [5].Our Pressure-Temperature Nomograph tool is an application of the Clausius-Clapeyron equation, which assumes the heat of vaporization is a constant over a pressure range. The Antoine equation gets around this assumption by using empirical data for .

3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.2/21/2017 Lab 3 Mohammad F Farooq O BJECTIVE The experiment aims at using non-destructive means/tests to obtain a rough estimate of the material's strength. To do the same students gain familiarity with Brinell, Rockwell testing machine and use Nomograph to obtain the corresponding tensile strength. I NTRODUCTION Non-destructive means/tests (NDT) are .The penetration test serves as a commonly adopted method to grade bitumen based on its hardness. Different grades are recommended for various climatic conditions and construction types. For instance, the Indian Road Congress (IRC) suggests bitumen grades such as 30/40, 60/70, and 80/100 for bituminous macadam and penetration macadam applications. The Leeb Hardness Test, also known as the rebound hardness test, measures hardness by analyzing the rebound of an indenter, rather than the size of an indentation. It is portable and ideal for on-site testing of large and heavy components, offering a non-destructive method that causes minimal damage to finished parts and coatings.

tomato soil moisture meter

Sequência de Derrotas - Série A – Probabilidades no Futebo.

hardness test nomograph|hardness testing methods pdf